Here's the above mention post about resin 3D printing: MoonRay Dental 3D Printer From SprintRay Poised For Digital Dentistry Future. As for which print is which? The one on the left is the filament and the one on the right is resin.AST2 is an authorized reseller for full range of Artec 3D scanners and software.

This one is of Arnold Schwarzenegger getting 3d scanned for Terminator Genisys by Legacy Effects. One of my favorite use cases is seeing this scanner in action at a school in Hawaii using it for an historical preservation class: 3D scanning with Artec enriches learning experience at Mid-Pacific Institute. Note: If you want to see some professional results, and some fun 3D scans, check out Artec’s case study page. In fact, many of the best 3D prints are scanned first before being used in advanced 3D modeling software – part of why this market segment is booming. 3D printers are awesome, but for instant gratification, nothing beats a 3D scanner. ģD Printed Filament vs Resin Photo by TJ McCueĪfter traveling the USA on the 3DRV national roadtrip studying and researching 3D technologies in 2014, one of the things I loved the most was the 3D scanners.

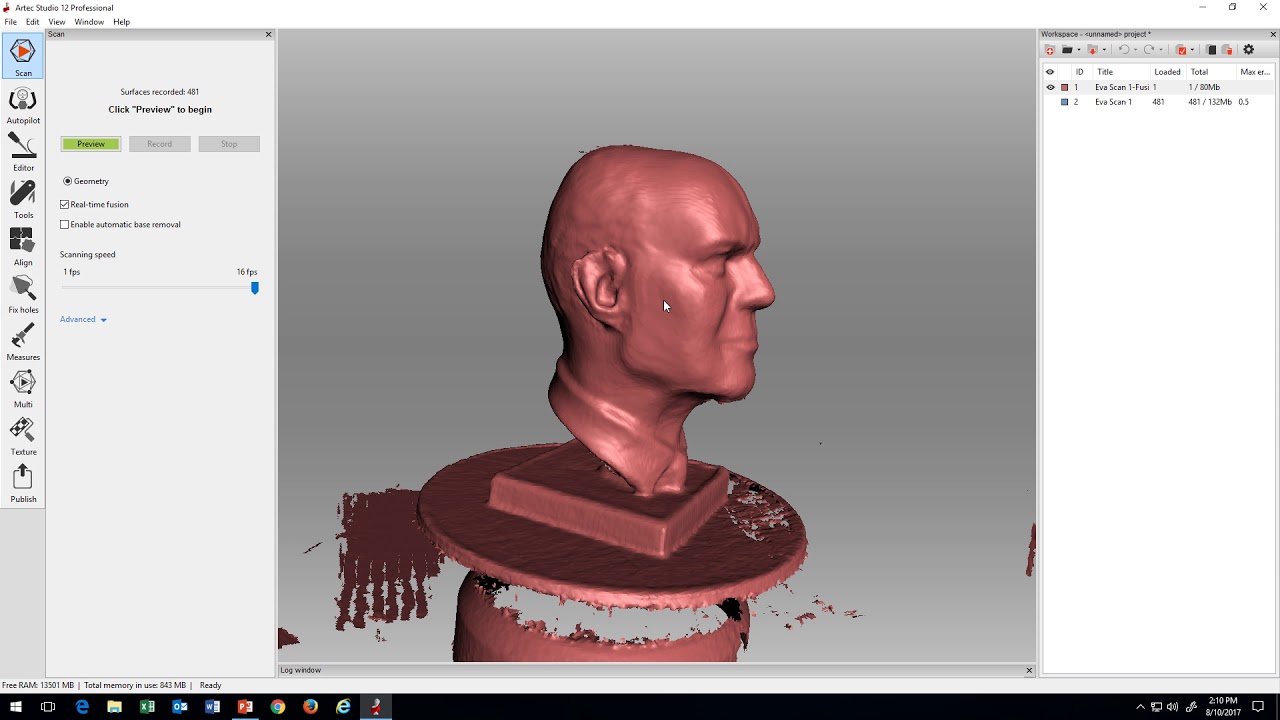

See if you can tell which one is the resin versus the filament print. Having done a lot of FDM/FFM 3D printing, I am also printing out some of these scans on the SprintRay / MoonRay DLP resin 3D printer. I did a bunch of scanning of friends so that we could 3D print a bust on an Ultimaker 3 (also a loaner). All in all, the Eva is very easy to learn and use. Despite that clunky scan above, the Artec Studio software allowed me to remove the extraneous data (scans) - it has an automated as well as manual option to do this. The software and scanner are essentially communicating with one another and so if you go too fast or move out of range the software beeps a warning and waits until you go back to that previous position, recalibrates, then lets you move forward. I could have figured it out on my own, but their tech support and training made it so much easier to understand and use. The Artec Eva workflow took some getting used to, but the company generously gave me some training (which is included for regular customers, of course, and is top-notch) and was available for support type questions via email as needed. As you can see above, our first scans (on left) were far from perfect, but the software helped us get to the image/model on the right.

0 kommentar(er)

0 kommentar(er)